Make Sure You Have the Right Router Cutters for Precision

If you're looking for the right tooling for your router cutters, why not consider our wide range of options? We have different types of bits available to help you customise your cutters for any kind of job. Choose CNC Router Bits when you need reliable access to reliable cutter extension bits.

Benefits of Choosing The Right Bit

CNC machines require different router cutters for different jobs. While the machine itself helps to save you time and money, the perfect compression cutter or bits are needed to create a high-quality final product. Here are a few benefits to choosing the correct bit for the job.

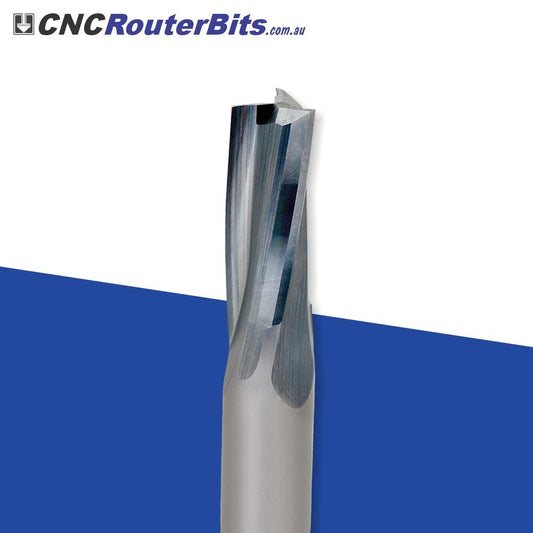

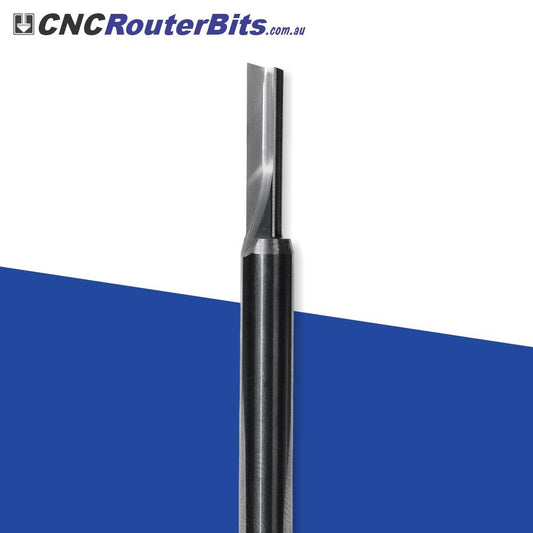

● Fabricate complicated designs. You’ll only be able to create complex designs if you select the correct bit for the job. Look carefully at the material you’re using and work from there. If you are working with complex wood grain, you may want to choose a spiral bit. If you’re working with wider, thicker materials, a straight cutter is going to be a better choice.

● Better chipload. Choosing the correct bit will ensure your chips are the right thickness so heat is transferred away from the bit. Too high a chipload leads to poor edge finishes and a transfer of cutting load, causing the bit to move. This affects the overall quality of your project.

● Overall quality. If you want a premium-quality result, it’s essential that you take the time to figure out which bit is going to get you the outcome you need. Understanding the fundamental differences between a spiral cutter and a straight bit will ensure you never choose the wrong bit for your CNC router.

● Affordability and value. It’s true, a straight bit is the more affordable option. That’s why many people choose it without considering the alternatives. However, if you’re looking to create a detailed design, a straight cutter may not be able to handle the complicated nature of the project. The result will be low quality and you may have to start again, causing more cost in wasted materials. Whether you use an up-cut or down-cut spiral bit, make sure you choose wisely before applying it to your CNC router.

Having a CNC machine will aid your business tremendously when you need to do any cutting. But it does not stop there. You can further customise your router with a range of different cutters to get the most out of it.

What You Should Know About the Different Types of Routing Cutters

If you're relatively new to using your CNC machine, there is a host of things you need to keep in mind before you use it. Something we believe everyone should know about is the different types of bits available for their CNC. Here are some of your options:

● A straight bit. Most consider these a necessity in every workshop since they cut straight. Since straight cuts are by far the most common, anyone should be able to make good use of them in a workshop. Since they come in various sizes, you should easily find the options best suited to your specific task.

● A flush-trim router bit. Unlike the straight or rabbeting bits, the flush-trim bits are used when you want to trim a surface that involves more than one material. For example, you would use this to trim the edge of a veneered surface containing a substrate.

● A chamfer routing bit. These bits are most commonly used to cut a bevel into a piece of material at a specific angle. Whether you want to do this as decoration or to ease the edge's intensity, the chamfer routing bit will work wonderfully. Keep in mind that you can also use these bevelled edges to join constructions with multiple sides.

● An edge-forming bit. Unlike the chamfer bits that you can use for decorative or joining purposes, the edge forming bits are mainly for decorating purposes. These bits cut a rounded edge out of the material to create a specific visual aesthetic, commonly used on tables, for example.

While these are the main types of bits, remember that these are not the only options. If, for example, you need a spiral cutter, all you have to do is ask. Our team can help you browse through a wide range of options and can quickly assist you with choosing the best one for the job. We can even supply you with specialised bits, engraving tools, router collets, and more.

About Us and Our Services for a Compression Tool and Similar Bits

One of the main things that make CNC routers so incredible is their ability to work with multiple bits and pieces to tailor to your specific requirements. We always use our time to find new bits to sell. If you do not know which bit you need for a particular job, you can always contact our team and ask. We will do everything we can to make sure the next job you do with your CNC router delivers clean, reliable results.

Whether you want a spiral bit or a v cutter, always remember that we have a wide selection for you to browse. Call us today and tell our professionals which bits you need so that we can help you get back to your project as soon as possible.